West Country based design engineers, Sharp & Tappin Technologies have just released their latest Precision Composite Router (PCR) onto the UK market.

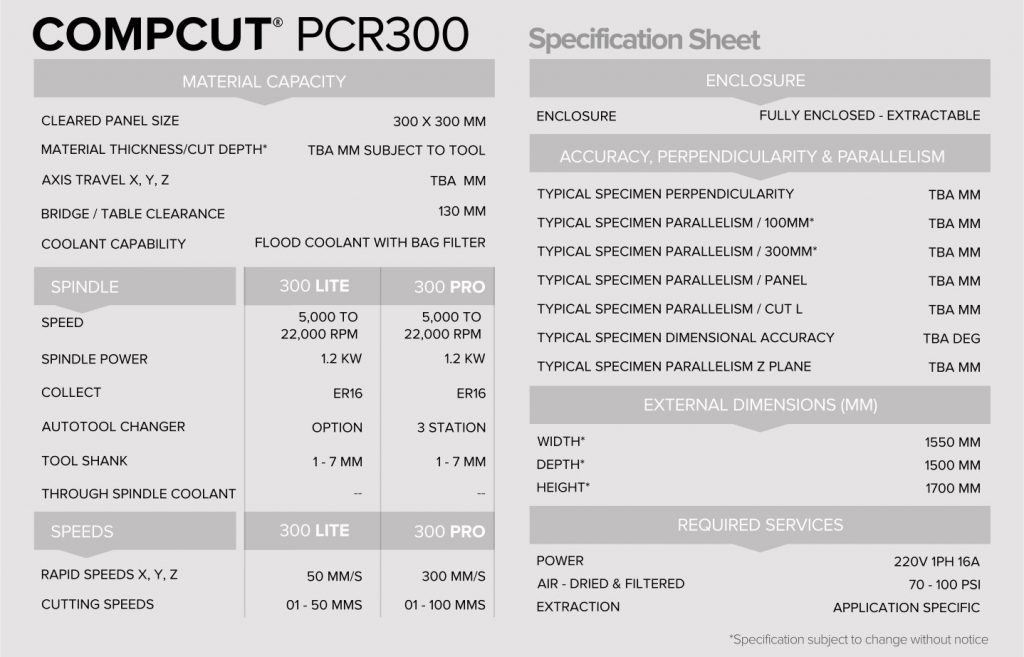

The new range of Precision Composite Routers complements and enhances the successful Compcut Saw Range by offering a true 3 axis machining capability.

Aimed initially to tackle complex geometry and high accuracy compression Composite test specimens, the PCR Routers also have an important role to play

in production trimming and second operation machining on finished components.

The introduction of the Compcut PCR 300 reflects Sharp & Tappin’s awareness of the growing demand in the UK market for precision machining solutions to create complex geometries from a wide range of advanced composites.

This new machine has been specifically designed to offer Composite R & D Teams and Test Centres affordable access to an ‘easy to use’ though intuitively sophisticated small form factor and extremely robust precision composite router.

The PCR 300 Router is available as a ‘Complete Solution Package’ incorporating a comprehensive range of cutting tools, work holding fixtures and a suite of machining

programmes that facilitate quick and easy operation.

Ben Sharp, Sharp & Tappin’s MD comments, ‘We have applied the same development approach to the PCR 300, that underpins the versatile Compcut

200 composite plate saw – creating a compact, easy to use machine that offers an affordable, high quality, composite ‘cutting solution’ – An advantage that small in-house test centres and R & D departments throughout the UK are beginning to recognise.’

Sharp & Tappin’s new Router range has been developed through a ‘proof of concept’ development programme run over the last three years in conjunction with

the prestigious National Composites Centre in Bristol. The test and trial results have led to the creation of what is essentially a ‘hybrid’

machining solution skilfully incorporating elements from CNC routers such as a high speed spindle, easy flat laminate compatibility together with the precision and flood

coolant capability associated with vertical machining centres encapsulated in a fully enclosed structure – to create what is effectively a new machining format, that is remarkably easy to use without the need for specific CNC expertise.

To fully appreciate the capabilities and potential of this unique new Router please view this video of the machine cutting some

dogbone samples from composite material:

For further information , please contact Jon Small, Business Development

Manager on +44 (0) 1409 253 534